X-35

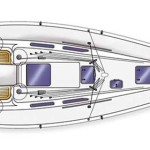

Hull – Quality in construction The use of heat galvanised steel to create a support structure for the mast and keel was pioneered by X-Yachts in 1981. Since then the Danish yard has produced more than 6,000 yachts featuring this technology and has won worldwide recognition for the strength of their designs. Her hull, keel and rudder configuration gives the helmsman a very light and direct feel of the yacht, and she responds immediately to minor corrections. Much attention has been paid to details on deck to make the X-35 easy to handle. Her cockpit is open and functional with a pleasingly clean layout. Her large wheel allows the helmsman to have a good view of the foresail, yet requires very little effort to steer her through the sea. Her refined control line system, on top of the coach roof, keeps the cockpit clutter-free, and allows easy and simple handling for both family and crew. A special feature is the jib in-hauler system for improved and effective jib control, which runs neatly under the deck and back to the cockpit. All the deck equipment has been specially selected from top market brands, in accordance with the X-35’s superior design and high performance criteria. The non-overlapping jib makes it easy for a shorthanded crew or family to sail the X-35, and an optional furling headstay converts the X-35 into a family friendly yacht. Hoisting the spinnaker downwind will bring a smile to the face of any sailor who likes to be on board a yacht that needs little encouragement to step up a gear or two. The foils are designed in-house, ensuring the X-35 rudder is a custom fit for the hull shape, underwater profile and sail plan. The rudder is designed for optimum ‘grip’ and maximum ‘feel’, giving responsive, reliable handling in all conditions and on all points of sail, and is constructed using high quality alloy stocks for a slim profile offering reduced resistance and underwater drag. The mahogany interior gives the saloon a welcoming feeling, and the forward double cabin is roomy and has additional storage below the berth and in the wardrobe. During racing the saloon table can be removed to create space for storing additional sails. The split pantry and navigation section includes a gas stove with two jets and oven, a sink, storage for cutlery and a coolbox. Piping for all the water systems on board run in dedicated service trays and channels. Custom-built high volume tanks for diesel fuel and water maximise the space usage underneath the saloon berths, and are also designed to optimise weight distribution by ensuring the fluids are carried low down in the hull. X-35

Deck – Easy handling

Control – Powerful and family friendly The sail plan, with the powerful main sail and 106% max jib, has the ability to accelerate the X-35 out of tacks, and keep her in the fast lane upwind.

The sail plan, with the powerful main sail and 106% max jib, has the ability to accelerate the X-35 out of tacks, and keep her in the fast lane upwind.

Keel & Rudder – Precision-engineered foils

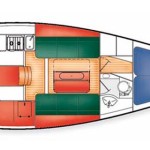

Owners cabin – For racing or summer holiday cruise The X-35 has sleeping accommodation for eight persons, and will comfortably take a family of four out on a summer holiday cruise.

The X-35 has sleeping accommodation for eight persons, and will comfortably take a family of four out on a summer holiday cruise.

Main cabin – Combining innovation with comfort

The mahogany interior is hand-polished with a satin finish; and the superb joinery reflects X-Yachts traditional craftsmanship, not only when new but also in the future.

The mahogany interior is hand-polished with a satin finish; and the superb joinery reflects X-Yachts traditional craftsmanship, not only when new but also in the future.

The glass fibre components, such as the engine box and the toilet section, are finished in a high gloss gelcoat that gives a modern and fresh look and, with the glass fibre head innerliner, comfort below deck is guaranteed in both warm and cold weather.

Galley and Working space – Room for all

The main switchboard can be fully controlled from the seat in front of the navigation area, and there is plenty of room forany navigation and electronic equipment needed by the owner.

Technical – Intelligent systems

Using the very latest 3D design programs, X-Yachts designers, engineers and technicians have been able to create a yacht where no space is wasted. The systems of the X-35 might be concealed from view, but they were incorporated into the yacht’s design and construction planning from the very outset. Every cable and pipe run is fully modeled in 3D to ensure that the system can be simply installed – and easily accessed for servicing at a later date.

Technical – Specifications

Draft – standard

2,15 m

Ballast – standard

1700 kg

Displacement light

4300 kg

Engine diesel

14,5 kW

Cabins, standard

3

Heads, standard

1